Geothermal

2021 ATB data for geothermal are shown above. These projections use bottom-up models derived from the analysis and results of the GeoVision: Harnessing the Heat Beneath our Feet report (DOE, 2019). The GeoVision report is a collaborative multiyear effort with contributors from industry, academia, national laboratories, and federal agencies. The analysis in the report updates resource potential estimates as well as current and projected capital and O&M costs through evaluation of current industry trends and predicted advancements in areas such as drilling efficiency and materials and enhanced geothermal system (EGS) stimulation success. Drilling and EGS improvements enable reduced development timelines, CAPEX, and financing rates.

The three scenarios for technology innovation are:

- Conservative Technology Innovation Scenario (Conservative Scenario): continuation of current industry trends in drilling (e.g., minor efficiency improvements with little to no increase in rate of penetration [ROP]) and EGS (e.g., limited increase in flow rate and stimulation success rate) resulting in minor CAPEX improvements by 2030

- Moderate Technology Innovation Scenario (Moderate Scenario): drilling advancements (e.g., doubled ROP and bit life and reduced number of casing intervals and associated drilling materials) detailed as part of the GeoVision report result in cost improvements that are achieved by 2030

- Advanced Technology Innovation Scenario (Advanced Scenario): substantial drilling and EGS advancements (e.g., significantly increased ROP, bit life, and EGS stimulation success, limited casing intervals, significantly reduced consumption of drilling materials, and reduced timelines) as modeled in the Technology Improvement scenario of the GeoVision report result in cost improvements that are achieved by 2030.

Resource Categorization

Within the 2021 ATB, geothermal resources broadly consist of two main types: hydrothermal and enhanced geothermal systems (EGS). Hydrothermal systems are naturally occurring zones of Earth-heated circulating fluid that can be exploited for electricity generation if certain minimum temperatures and flow rates are achieved for a given power plant technology. EGS exhibit naturally occurring zones of heat but lack sufficient fluid flow and require engineering to enhance permeability. These are then subdivided based on site specific resource characteristics and compatible power plant technology.

The two types of energy conversion processes used to generate geothermal electricity are: binary organic Rankine cycle and flash.

- Binary plants use a heat exchanger and secondary working fluid with a boiling point below that of water to transfer geothermal energy through an organic Rankine cycle. This technology generally applies to lower-temperature systems (<200°C) due to the current maximum operating temperature of pumping technology. These systems have higher CAPEX than flash systems because of the increased number of components, their lower-temperature operation, and a general requirement that a number of wells be drilled for a given power output.

- Flash plants generate steam through a pressure change of the thermal fluid that directly drives a turbine. This technology generally applies to higher-temperature systems. Because of the reduced number of components and higher-temperature operation, these systems generally produce more power per well, thus requiring fewer wells and reducing drilling costs. These systems generally have lower CAPEX than binary systems.

The ATB defines flash resources as those with temperatures at or above 200°C and binary resources as those with temperatures from 110 to <200°C. EGS resources are further subdivided into near-hydrothermal field EGS (NF-EGS) and deep EGS. The resulting geothermal resource supply curves (~139,000 MW) consist of six categories: hydrothermal flash, hydrothermal binary, NF-EGS flash, NF-EGS binary, deep EGS flash, and deep EGS binary. For illustration in the ATB, six representative geothermal plants are shown with design parameters based on each respective resource category.

Examples using these plant types in each of the three resource categories (hydrothermal, NF-EGS, and deep EGS) are shown in the ATB.

| Technology | Temp (°C) | >=200C | 150–200 | 135–150 | <135 |

|---|---|---|---|---|---|

| Hydrothermal | Number of identified sites | 21 | 23 | 17 | 59 |

| Total capacity (MW) | 15,338 | 2,991 | 820 | 4,632 | |

| Average OCC ($/kW) | 4,175 | 8,829 | 9,476 | 17,757 | |

| Min OCC ($/kW) | 3,000 | 4,397 | 7,444 | 11,884 | |

| Max OCC ($/kW) | 5,971 | 38,720 | 11,781 | 25,934 | |

| Example of plant OCC ($/kW) | 4,498 | 5,760 | N/A | ||

| NF-EGS | Number of sites | 12 | 20 | ||

| Total capacity (MW) | 787 | 596 | |||

| Average OCC ($/kW) | 11,429 | 27,330 | |||

| Min OCC ($/kW) | 9,026 | 18,974 | |||

| Max OCC ($/kW) | 18,797 | 41,694 | |||

| Example of plant OCC ($/kW) | 13,940 | 32,147 | |||

| Deep EGS (3–6 km) | Number of sites | N/A | N/A | N/A | |

| Total capacity (MW) | 100,000+ | ||||

| Average OCC ($/kW) | 28,991 | 65,081 | |||

| Min OCC ($/kW) | 18,733 | 40,515 | |||

| Max OCC ($/kW) | 54,987 | 96,405 | |||

| Example of plant OCC ($/kW) | 13,940 | 32,147 | |||

OCC: overnight capital cost

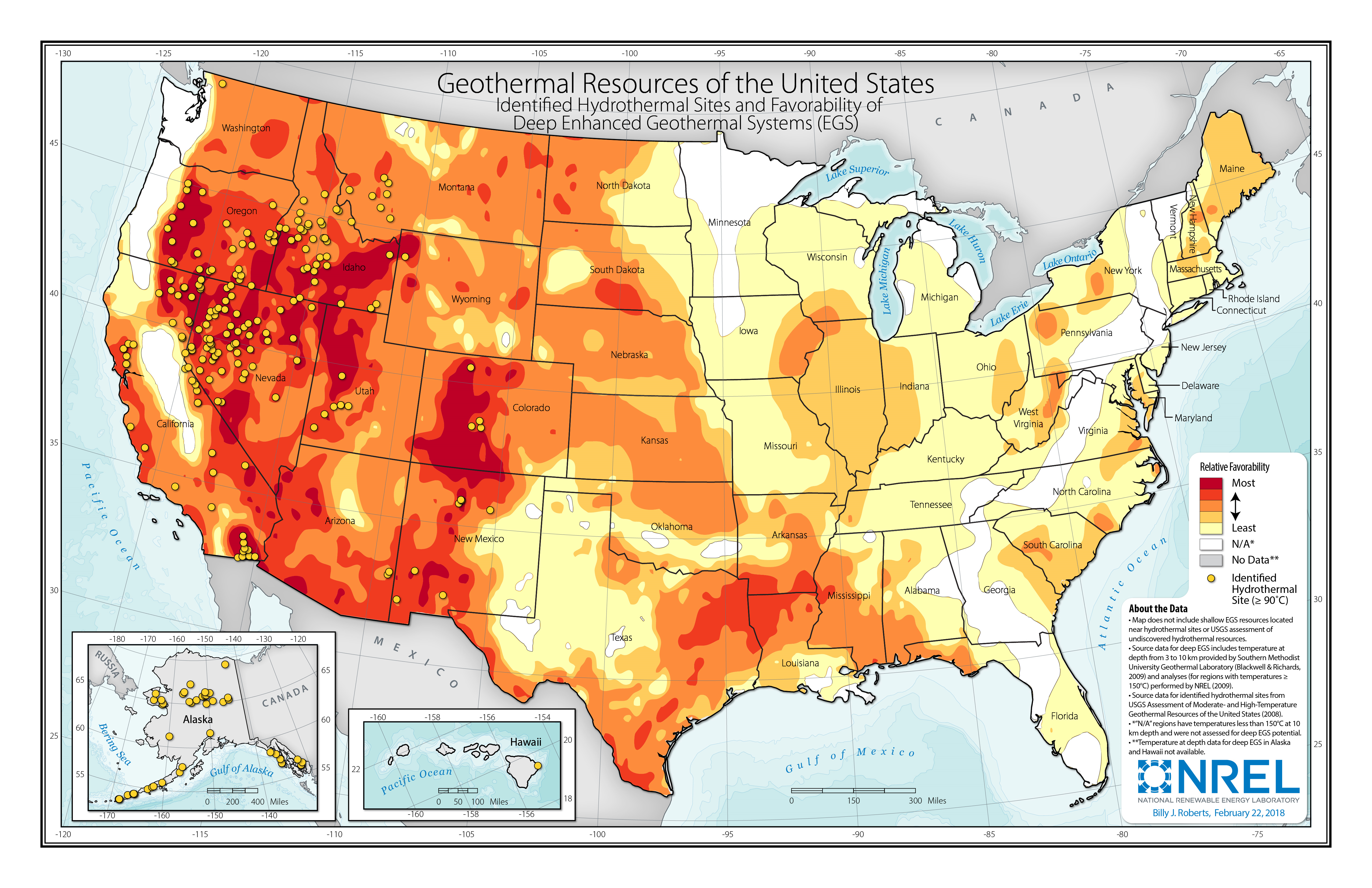

The hydrothermal geothermal resource potential is concentrated in the western United States. The total mean potential estimated by the U.S. Geological Survey (USGS) in 2008 is 39,090 MW: 9,057 MW identified and 30,033 MW undiscovered (USGS, 2008). The resource potential identified at each site is based on available reservoir thermal energy information from studies conducted at the site (USGS, 2008). The undiscovered hydrothermal resource estimate is based on a series of geographic information system (GIS) statistical models of the spatial correlation of geological factors that facilitate the formation of geothermal systems.

The USGS resource potential estimates for hydrothermal are used with the following modifications:

- Installed capacity of about 3 GW in 2018 is excluded from the resource potential.

- Resources on federally protected and U.S. Department of Defense lands, where development is highly restricted, are excluded from the resource potential, as are resources on lands where significant barriers that prevent or inhibit development of geothermal projects were identified by Augustine, Ho, and Blair (Augustine et al., 2019).

The EGS resource potential is concentrated in the western United States, but technology innovations as described in the Advanced Scenario would increase potential beyond the western United States. The total potential is greater than 100,000 MW: 1,493 MW of NF-EGS and the remainder from deep EGS. The NF-EGS resource potential is based on data from USGS for EGS potential on the periphery of select identified hydrothermal sites (Augustine et al., 2019). The deep EGS resource potential ((Roberts, 2018); (Augustine, 2016)) is based on Southern Methodist University Geothermal Laboratory temperature-at-depth maps and the methodology is from (Tester et al., 2006).

Scenario Descriptions

| Scenario | Drilling Advancements | EGS Development |

|---|---|---|

| Conservative Scenario | Technology Description: Drilling efficiency improvements (e.g., using mechanical specific energy with polycrystalline diamond compact bits and limiting bit dysfunction leads to longer bit life) result in minor decreases in drilling costs and little to no timeline reduction. Justification: Substantial increases in drilling ROP are unlikely without wider adoption of oil and gas technologies and new bit innovations. | Technology Description: Current well stimulation techniques do not consistently generate adequate economic flow rates of sustained flow from unsuccessful wells leading to little to no improvement of drilling success rate or CAPEX reduction. Justification: Stimulation is cost prohibitive and lacks zonal isolation. Both the precision and scale of stimulation must improve. |

| Moderate Scenario | Technology Description: ROP and bit life are doubled. Timelines and consumption of drilling materials are reduced. Justification: Cost modeling of drilling improvements along with limited successful field demonstrations and abundant oil and gas experience confirm this level of advancement is achievable (Lowry et al., 2017a) (Lowry et al., 2017b); (Hackett et al., 2020).

| Technology Description: As above, stimulation techniques remain cost prohibitive. Justification: To remain consistent with the GeoVision report, cost modeling for stimulation technology has yet to be performed for a mid-case scenario. Additionally, successful deployment of EGS technology is modeled as coupled with significant drilling advancements as lower drilling costs and improved directional drilling in hard rock environments will likely help enable EGS reservoir development. |

| Advanced Scenario | Technology Description: ROP and bit life are increased 4x over conservative. Wells are constructed as mono-bore using expandable casing. The increased speeds result in significantly shorter timelines and lower consumption of drilling related materials. Justification: Ongoing Advanced Research Projects Agency-Energy (ARPA-E), Sandia National Laboratories, NLR, and other research (e.g., laser drilling and electric pulse research) is directed at reducing the cost, style, and duration of well drilling. Growing interest from the oil and gas sector is leading to knowledge transfer. | Technology Description: Stimulation success rate, control, and sustained flow rate advance to economic levels. Justification: The ongoing EGS Collab, FORGE project, and other U.S. Department of Energy (DOE) Geothermal Technologies Office-sponsored research are demonstrating stimulation techniques in hard rock environments, including hydraulic shearing, zonal isolation, and other techniques. |

| Impact |

|

|

| References |

|

Representative Technology

| Scenario | Rate of Penetration (ft/hr) | Bit Life (hr) | EGS Flow Rate (kg/s) |

|---|---|---|---|

| Conservative (2018) | 25 | 50 | 40 |

| Moderate | 50 | 100 | 40 |

| Advanced | 100 | 200 | 80 flash/110 binary |

Hydrothermal

Hydrothermal geothermal technologies encompass technologies for exploring for the resource, drilling to access the resource, and building power plants to convert geothermal energy to electricity. Technology costs depend heavily on the hydrothermal resource temperature and well productivity and depth, so much so that project costs are site-specific and a "typical" cost applied to any given site would be inaccurate. The 2021 ATB uses scenarios developed by the DOE Geothermal Technologies Office (Mines, 2013) for representative binary and flash hydrothermal power plant technologies.

The first scenario assumes a 175°C resource at a depth of 1.5 km with wells producing an average of 110 kg/s of geothermal brine supplied to a 30-MWe binary (organic Rankine cycle) power plant. The second scenario assumes a 225°C resource at a depth of 2.5 km with wells producing 80 kg/s of geothermal brine supplied to a 40-MWe dual-flash plant. These are mid-grade or "typical" temperatures and depths for binary and flash hydrothermal projects.

The 2021 ATB representative technologies fall in the middle or near the end of the hydrothermal resources cost estimates typically deployed in Regional Energy Deployment System (ReEDS) model runs.

Enhanced Geothermal Systems

As with costs for projects that use hydrothermal resources, EGS resource project costs depend so heavily on the hydrothermal resource temperature and well productivity and depth that project costs are site-specific. The 2021 ATB uses scenarios developed by the DOE Geothermal Technologies Office (Mines, 2013) for representative binary and flash EGS power plants assuming current (immature) EGS technology performance metrics. The first scenario assumes a 175°C resource at a depth of 3 km with wells producing an average of 40 kg/s of geothermal brine supplied to a 25-MWe binary (organic Rankine cycle) power plant. The second scenario assumes a 250°C resource at a depth of 3.5 km with wells producing 40 kg/s of geothermal brine supplied to a 30-MWe dual-flash plant. These temperatures and depths are at the low-cost end of the EGS supply curve and would be some of the first developed.

Methodology

This section describes the methodology to develop assumptions for CAPEX, O&M, and capacity factor. For standardized assumptions, see labor cost, regional cost variation, materials cost index, scale of industry, policies and regulations, and inflation.

The site-specific nature of geothermal plant cost, the relative maturity of hydrothermal plant technology, and the very early stage development of EGS technologies make cost projections difficult. The GeoVision scenarios were based on bottom-up analysis of potential cost and performance improvements. The inputs for these scenarios were developed by the national laboratories as part of the GeoVision effort and were reviewed by industry experts.

The cost and performance estimates are calculated using Geothermal Electricity Technology Evaluation Model (GETEM), a bottom-up cost analysis tool that accounts for each phase of development of a geothermal plant.

- Cost and performance data for hydrothermal generation plants are estimated for each potential site using GETEM. Model results are based on resource attributes (e.g., estimated reservoir temperature, depth, and potential) of each site.

- Site attribute values are from (USGS, 2008) for identified resource potential and from capacity-weighted averages of site attribute values of nearby identified resources for undiscovered resource potential.

- GETEM is used to estimate CAPEX, O&M, and parasitic plant losses that affect net energy production for the three technology innovation scenarios.

Capital Expenditures (CAPEX)

Definition: For the ATB—and based on (EIA, 2016) and GETEM component cost calculations—the geothermal plant envelope is defined to include:

- Geothermal generation plant

- Exploration, confirmation drilling, well field development, reservoir stimulation (EGS), plant equipment, and plant construction

- Power plant equipment, well-field equipment, and components for wells (including dry/noncommercial wells)

- Balance of system (BOS)

- Installation and electrical infrastructure, such as transformers, switchgear, and electrical system connecting turbines to each other and to the control center

- Project indirect costs, including costs related to engineering, distributable labor and materials, construction management start-up and commissioning, and contractor overhead costs, fees, and profit

- Financial costs

- Owners' costs, such as development costs, preliminary feasibility and engineering studies, environmental studies and permitting, legal fees, insurance costs, and property taxes during construction

- Electrical interconnection and onsite electrical equipment (e.g., switchyard), a nominal-distance spur line (<1 mile), and necessary upgrades at a transmission substation; distance-based spur line cost (grid connection costs, or GCC) not included in the ATB

- Interest during construction estimated based on 4-year and 5-year durations for hydrothermal and EGS respectively (for the Advanced Scenario), 7-year and 9-year durations for hydrothermal and EGS respectively (for the Moderate Scenario), and 8-year and 10-year durations for hydrothermal and EGS respectively (for the Conservative Scenario), accumulated at different intervals for hydro and EGS based on schedules as outlined by the GeoVision Study (ConFinFactor).

In the ATB, CAPEX is shown for six representative plants. CAPEX estimates for all hydrothermal NF-EGS potential result in a CAPEX range that is much broader than that shown in the ATB. It is unlikely that all the resource potential will be developed because of the high costs for some sites. Effects of regional cost variation and distance-based spur line costs are not estimated.

CAPEX in the ATB does not represent regional cost variants (CapRegMult) associated with labor rates, material costs, and other factors (CapRegMult = 1).

CAPEX in the ATB does not include geographically determined spur line (GCC) costs from plant to transmission grid (GCC = 0).

Base Year: GETEM inputs are derived from the Business-as-Usual (BAU) scenario from the GeoVision report ((DOE, 2019), (Augustine et al., 2019)). Costs are for new or greenfield hydrothermal projects, not for redrilling or additional development/capacity additions at an existing site. The following chart shows historical CAPEX and LCOE for geothermal, including data from IRENA (IRENA, 2019).

Future Years: Projection of future geothermal plant CAPEX for three scenarios are derived from modeled costs in the GeoVision report as follows:

- Conservative Scenario: Continuation of current industry trends in drilling (e.g., minor efficiency improvements with little to no increase in ROP) and EGS (e.g., subeconomic flow rates and limited stimulation reproducibility) result in a minimum learning rate and minor CAPEX improvements as implemented in the U.S. Energy Information Administration's Annual Energy Outlook 2015 (EIA, 2015): 10% CAPEX reduction by 2035. This corresponds to a 0.5% annual improvement in CAPEX, which is assumed to continue through 2050.

- Moderate Scenario: Drilling advancements, specifically the Intermediate 1 Drilling Curve (e.g., doubled ROP and bit life and reduced number of casing intervals, associated drilling materials, and timelines) detailed as part of the GeoVision report, result in cost improvements that are achieved by 2030. Costs decrease linearly from present values to the 2030 projected values followed by a 0.5% annual reduction in CAPEX, due to a minimum learning rate, through 2050.

- Advanced Scenario: Significant drilling and EGS advancements as modeled in the Technology Improvement scenario of the GeoVision report result in cost improvements that are achieved by 2030. Costs decrease linearly from present values to the 2030 projected values and are followed by a 0.5% annual reduction in CAPEX, due to a minimum learning rate, through 2050. Drilling improvements, as part of the GeoVision Ideal Drilling Curve, include significantly increased ROP, bit life, and EGS stimulation success, limited casing intervals, and significantly reduced consumption of drilling materials.

Use the following table to view the components of CAPEX.

Operation and Maintenance (O&M) Costs

Definition: Fixed O&M (FOM) costs represent average annual fixed expenditures (and depend on rated capacity) required to operate and maintain a hydrothermal plant over its lifetime of 30 years (plant and reservoir), including:

- Insurance, taxes, land lease payments, and other fixed costs

- Present value and annualized large component overhaul or replacement costs over technical life (e.g., downhole pumps)

- Scheduled and unscheduled maintenance of geothermal plant components and well-field components over the technical lifetime of the plant and reservoir.

Base Year: GETEM is used to estimate FOM for each of the six representative plants. FOM for NF-EGS and EGS are equivalent.

Future Years: Future FOM cost reductions are based on results from the GeoVision Technology Improvement scenario (DOE, 2019) and are described in detail in Augustine, Ho, and Blair (Augustine et al., 2019).

Use the following table to view the components of operating expenditures.

Capacity Factor

Definition: Geothermal plant capacity factor is influenced by diurnal and seasonal air temperature variation (for air-cooled plants), technology (e.g., binary or flash), downtime, and internal plant energy losses.

Estimates of capacity factor for geothermal plants in the ATB represent typical operation.

Base Year: The capacity factor estimates are developed using GETEM at typical design air temperature and based on design plant capacity net losses. An additional reduction is applied to approximate potential variability that is due to seasonal temperature effects.

Some geothermal plants have experienced year-on-year reductions in energy production, but this is not consistent across all plants. No approximation of long-term degradation of energy output is assumed.

Future Years: Capacity factors remain unchanged from the Base Year through 2050. Technology improvements are focused on CAPEX costs. The dispatch characteristics of these systems can be valuable to the electric system to manage changes in net electricity demand. Actual capacity factors will be influenced by the degree to which system operators call on geothermal plants to manage grid services. However, a constant dispatch profile is modeled in the ATB and no change is assumed over time.

References

The following references are specific to this page; for all references in this ATB, see References.