Residential Battery Storage

The 2021 ATB represents cost and performance for battery storage with two representative systems: a 3 kW / 6 kWh (2 hour) system and a 5 kW / 20 kWh (4 hour) system. It represents lithium-ion batteries only at this time. There are a variety of other commercial and emerging energy storage technologies; as costs are well characterized, they will be added to the ATB.

The NLR Storage Futures Study has examined energy storage costs broadly and specifically the cost and performance of lithium-ion batteries (LIBs) (Augustine and Blair, 2021). The costs presented here (and for distributed commercial storage and utility-scale storage) are based on this work. This work incorporates current battery costs and breakdown from the Feldman 2021 report (Feldman et al., 2021) that works from a bottom-up cost model. The bottom-up battery energy storage systems (BESS) model accounts for major components, including the LIB pack, inverter, and the balance of system (BOS) needed for the installation. We would note though that, during the elapsed time between the calculations for the Storage Futures Study and the ATB release, updated values have been calculated as more underlying data have been collected. While these changes are small, we recommend using the data presented here in the ATB rather than what was previously published with the Storage Futures Study.

Current (2020) costs for residential BESS are based on NLR's bottom-up BESS cost model using the data and methodology of (Feldman et al., 2021), who estimated costs for both AC- and DC-coupled systems for a less-resilient (3 kW/6 kWh) installation and a more-resilient (5 kW/20 kWh) installation. We use the same model and methodology but do not restrict the power or energy capacity of the BESS to two options. Key modeling assumptions and inputs are shown in Table 1. We assume 2020 battery pack costs of $248/kWhDC 2019 USD (Bloomberg New Energy Finance (BNEF), 2019).

| Model Component | Modeled Value | Description |

| System size | 3-8 kW power capacity 2-4 E/P ratio | Battery capacity is in kWDC. E/P is battery energy to power ratio and is synonymous with storage duration in hours. |

| Battery pack cost | $252/kWh | Battery pack only (Bloomberg New Energy Finance (BNEF), 2019) |

| Battery-based inverter cost | $488/kW | Assumes a bidirectional inverter (Bloomberg New Energy Finance (BNEF), 2019), converted from $/kWh for 5 kW/14 kWh system |

| Supply-chain costs | 6.86% (U.S. average) | U.S. average sales tax on equipment |

| Installation labor cost | Electrician: $28.90/hour Laborer: $19.69/hour | Assumes U.S. average pricing |

| Engineering fee | $102 | Engineering design and professional engineer-stamped calculations and drawings |

| Permitting, inspection, and interconnection | Electrician: $29.74/hour | 20/32 hours (DC-coupled/AC-coupled) of commissioning and interconnection labor, and permit fee |

| Sales and marketing (customer acquisition) | $0.62/WDC | 20 additional hours for DC system, and 32 additional hours for AC system, per closed sale, associated with selling a PV system with storage |

| Overhead (general and administrative) | $0.29/WDC | Rent, building, equipment, staff expenses not directly tied to permitting, inspection, and interconnection; customer acquisition; or direct installation labor |

| Profit (%) | 17% | Fixed percentage margin applied to all direct costs including hardware, installation labor, direct sales and marketing, design, installation, and permitting fees. |

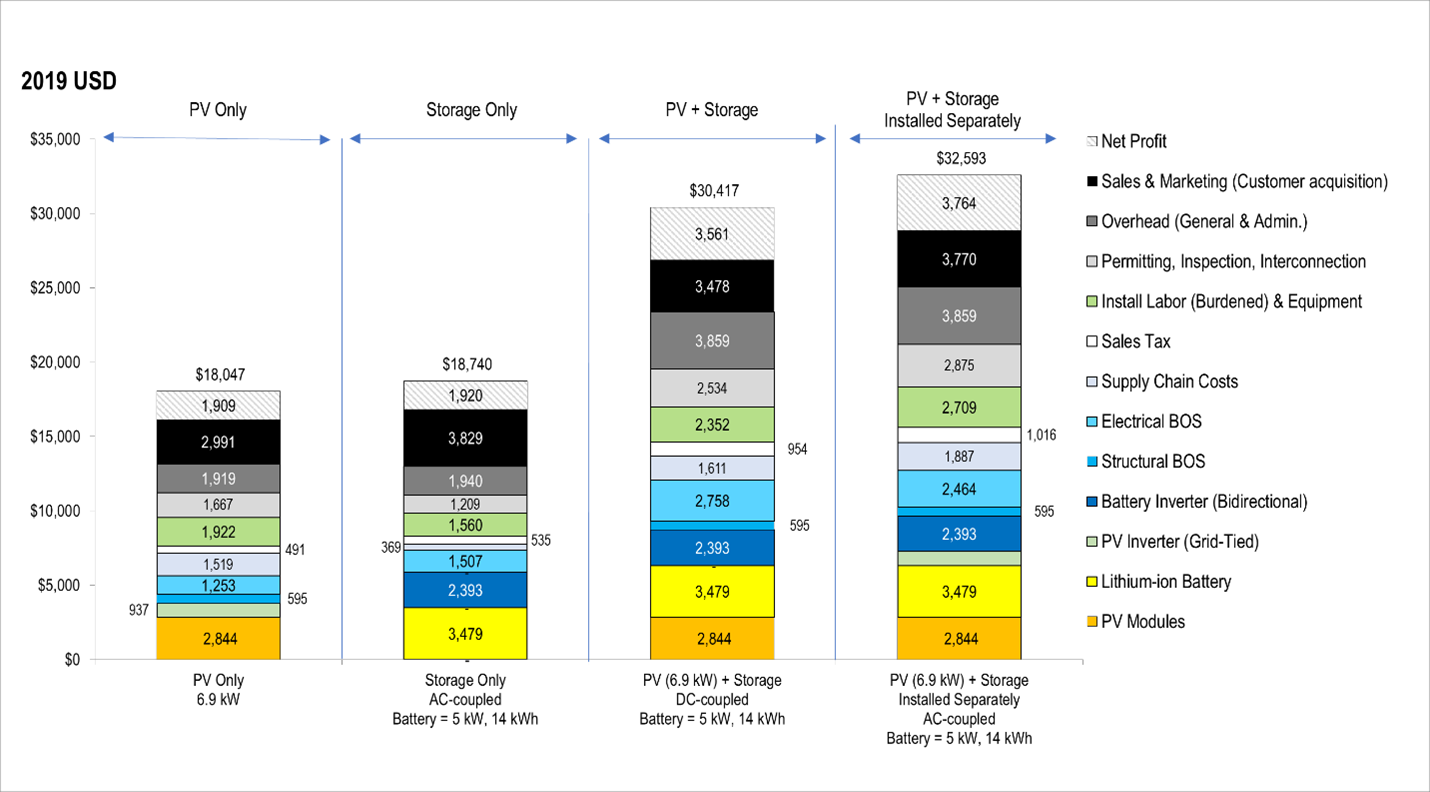

Residential BESS can be installed separately or can be added to an existing PV system (as an AC-coupled system). We also consider the installation of PV systems combined with BESS (PV+BESS) systems. Costs for residential PV systems come from NLR's bottom-up PV cost model (Feldman et al., 2021). We do include some cost savings for a combined PV and battery storage system. We assume the electrical BOS and installation labor are 90% of what they would be if the systems were installed separately. We also assume the sales and marketing costs for PV+BESS includes the cost of 20 more hours for a DC-coupled system and 32 more hours for an AC-coupled system than would be included for a PV-only system installation ((Feldman et al., 2021), Table 10). For the PV systems shown in Figure 36, this adds 20%–30% to customer acquisition costs. The resulting cost estimates are shown in Figure 1.

As with utility-scale BESS, the cost of a residential BESS is a function of both the power capacity and the energy storage capacity of the system, and both must be considered when estimating system cost. Furthermore, the Distributed Generation Market Demand (dGen) model does not assume specific BESS system sizes and it needs an algorithm to estimate residential BESS system cost based on the attributes of the residences (agents) it generates.

We develop an algorithm for stand-alone residential BESS cost as a function of power and energy storage capacity using the NLR bottom-up residential BESS cost model (Feldman et al., 2021) with some modifications. The NLR bottom-up model assumes either a 6-kW (less-resilient) or an 8-kW (more-resilient) inverter, which introduces a step function to the model and limits system size. We update the model to assume inverter costs of $0.48/WDC, which is consistent with BNEF estimates for inverter costs (Bloomberg New Energy Finance (BNEF), 2019). We then run the model for BESS with 3 kW–10 kW of power capacity and 4 kWh–50 kWh of energy storage capacity. We achieve a near-perfect fit for all systems by fitting the costs to a linear equation with three constants:

- BESS cost (total $) = $1,690/kW * PB + $354/kWh * EB + $5,982

where PB = battery power capacity (kW) and EB = battery energy storage capacity ($/kWh).

Scenario Descriptions

Available cost data and projections are very limited for distributed battery storage. Therefore, the battery cost and performance projections in the 2021 ATB are based on the same literature review as for utility-scale and commercial battery cost projections. The projections are based on a literature review of 19 sources published in 2018 or 2019, as described by Cole and Frazier (Cole and Frazier, 2020). Three projections from 2019 to 2050 are developed for scenario modeling based on this literature.

- Conservative Technology Innovation Scenario (Conservative Scenario): The conservative projection is comprised of the the maximum projection in 2020, 2025, and 2030 amongst the 19 projections reviewed . Defining the 2050 points is more challenging because only four data sets extend to 2050; they show cost reductions of 19%, 25%, 27%, and 39% from 2030 to 2050. The 25% is used for the moderate and conservative scenarios. In other words, the Conservative Scenario is assumed to decline by 25% from 2030 to 2050.

- Moderate Technology Innovation Scenario (Moderate Scenario): The moderate projections are taken as the as the median point in 2020, 2025, and 2030 of the 19 projections reviewed. Defining the 2050 points is more challenging because only four data sets extend to 2050; they show cost reductions of 19%, 25%, 27%, and 39% from 2030 to 2050. The 25% is used for the moderate and conservative cases. In other words, the Moderate Scenario is assumed to decline by 25% from 2030 to 2050.

- Advanced Technology Innovation Scenario (Advanced Scenario): The advanced projections are taken as the as the lowest cost point in 2020, 2025, and 2030 of the 19 projections reviewed. Defining the 2050 points is more challenging because only four data sets extend to 2050; they show cost reductions of 19%, 25%, 27%, and 39% cost reduction from 2030 to 2050. The 39% is used for the Advanced Scenario. In other words, the Advanced Scenario is assumed to decline by 39% from 2030 to 2050.

Methodology

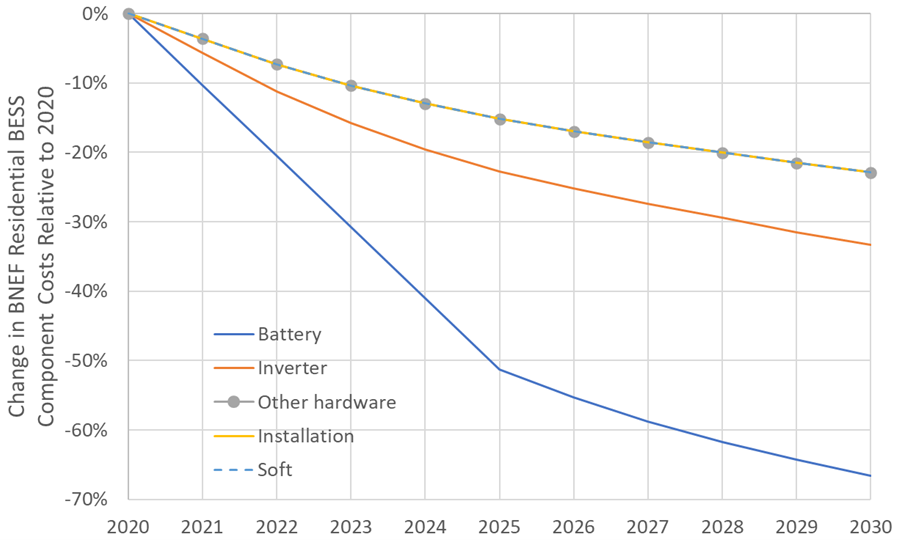

NLR has not maintained future cost projections for residential BESS for the ATB as it has for utility-scale systems. In their absence, we base residential BESS cost projections on the NLR bottom-up cost model for residential systems combined with component cost projections from BNEF. BNEF has published cost projections for a 5-kW/14-kWh BESS system through 2030 (Frith, 2020), with the projections being based on learning rates and future capacity projections.

Data Source: (Bloomberg New Energy Finance (BNEF), 2019)

The following methodology involves the following the steps to generate the Moderate Scenario future cost projections in detail:

- Estimate current costs for a range of BESS power and energy capacity combinations using the NLR bottom-up residential BESS cost model.

- Total and component cost results are recorded.

- Component costs are assigned to categories according to Table 4.

- Moderate Scenario: For each future year, apply cost reductions.

- Apply cost reductions from the BNEF projections (Frith, 2020) to the corresponding component cost category for each BESS considered.

- BNEF projections only go to 2030. We assume residential BESS component costs decline by an additional 25% from 2030 to 2050, similar to the assumption used in the ATB utility-scale BESS cost projections (Cole and Frazier, 2020).

- Advanced and Conservative Scenarios: Apply cost projections from the corresponding ATB utility-scale BESS scenario to all component costs.

- Sum the component costs to get the total BESS cost in future years. For each future year, develop a linear correlation relating BESS costs to power and energy capacity:

- BESS cost (total $) = ca * PB + c2 * EB + c3

- Where PB = battery power capacity (kW) and EB = battery energy storage capacity ($/kWh), and ci = constants specific to each future year

Capital Expenditures (CAPEX)

Definition: The bottom-up cost model documented by (Feldman et al., 2021) contains detailed cost buckets for both solar only, battery only, and combined systems costs. Though the battery pack is a significant cost portion, it is a minority of the cost of the battery system. This cost breakdown is different if the battery is part of a hybrid system with solar PV or a stand-alone system. The total costs by component for residential-scale stand-alone battery are demonstrated in Table 2 for two different example systems.

| AC Coupled 3 kW/6 kWh (Total $) | AC Coupled 5 kW/20 kWh (Total $) | |

| Battery Pack | $1,503 | $5,009 |

| Inverter | $1,034 | $3,445 |

| BOS | $1,461 | $1,461 |

| Supply Chain Costs | $200 | $496 |

| Sales Tax | $264 | $619 |

| Install Labor & Equipments | $1,194 | $1,384 |

| Engineering Fee | $99 | $99 |

| PII | $1,176 | $1,176 |

| Sales & Marketing | $2,500 | $3,708 |

| Overhead & Profit | $2,858 | $4,644 |

| Total | $12,287 | $22,041 |

Base Year: The Base Year cost estimate is taken from (Feldman et al., 2021) and is currently in 2019$.

Within the ATB Data spreadsheet, costs are separated into energy and power cost estimates, which allows capital costs to be constructed for durations other than 4 hours according to the following equation:

Total System Cost ($/kW) = (Battery Pack Cost ($/kWh) × Storage Duration (hr) + Battery Power Capacity (kW) × BOS Cost ($/kW) + Battery Power Constant ($)) / Battery Power Capacity (kW)

For more information on the power versus energy cost breakdown, see (Cole and Frazier, 2020).

Future Projections: Future projections are based on the same literature review data that informs Cole and Frazier (Cole and Frazier, 2020)., which generally used the median of published cost estimates to develop a Mid Technology Cost Scenario and the minimum values to develop a Low Technology Cost Scenario. However, as the battery pack cost is anticipated to fall more quickly than the other cost components (which is similar to the recent history of PV system costs), the battery pack cost reduction is taken from BNEF (Frith, 2020)and reduced more quickly. This tends to make the longer-duration batteries (e.g., 10 hours) decrease more quickly while short duration (e.g., 2 hours) decrease less quickly into the future. All durations trend toward a common trajectory as battery pack costs decrease into the future.

Operation and Maintenance (O&M) Costs

Base Year: Cole and Frazier (Cole and Frazier, 2020). assume no variable O&M (VOM) cost. All operating costs are instead represented using fixed O&M (FOM) costs. They include augmentation costs needed to keep the battery system operating at rated capacity for its lifetime. In the 2020 ATB, FOM is defined as the value needed to compensate for degradation to enable the battery system to have a constant capacity throughout its life. According to the literature review (Cole and Frazier, 2020), FOM costs are estimated at 2.5% of the capital costs in dollars per kilowatt.

Future Years: In the 2021 ATB, the FOM costs and VOM costs remain constant at the values listed above for all scenarios.

Capacity Factor

The cost and performance of the battery systems are based on an assumption of approximately one cycle per day. Therefore, a 4-hour device has an expected capacity factor of 16.7% (4/24 = 0.167), and a 2-hour device has an expected capacity factor of 8.3% (2/24 = 0.083). Degradation is a function of this usage rate of the model and systems might need to be replaced at some point during the analysis period. We use the capacity factor for a 4-hour device as the default value for ATB.

Round-Trip Efficiency

Round-trip efficiency is the ratio of useful energy output to useful energy input. (Mongird et al., 2020) identified 86% as a representative round-trip efficiency, and the 2021 ATB adopts this value.

References

The following references are specific to this page; for all references in this ATB, see References.