Fossil Energy Technologies

For the 2022 ATB the DOE Office of Fossil Energy and Carbon Management (FE) focused on providing updated cost and performance information for conventional natural gas-fueled and pulverized coal (PC) technology options represented in the 2020 ATB. Data for systems equipped with CO2 capture greater than 90% have been added in a mid-year update to the 2022 ATB. Future FECM participation is anticipated to result in expansion of fossil technology options, which may include retrofit options for existing coal and natural gas-fueled options.

Estimates of cost and performance for currently available fossil-fueled electricity generating technologies are representative of current commercial offerings and/or projects that began commercial service within the past 10 years.

Estimates of performance and costs for future fossil-fueled electricity generating technology options are meant to capture incremental cost reductions that occur over time (e.g., learning-by-doing improvements that are most often the result of more process design optimization and/or reduced costs that are due to improvements in equipment manufacturing practices) as well as deployment of advanced technologies that result from research and development (R&D).

Estimates of future fossil technology performance and cost for the three 2022 ATB technology innovation scenarios reflect the following assumptions:

- Conservative Technology Innovation Scenario (Conservative Scenario): minor reductions in capital costs through 2050 due to learning-by-doing for all fossil technologies; minor efficiency improvements for coal-fueled integrated gasification combined cycle (IGCC) in the near-term (i.e., through 2030) that could be expected based on lessons learned from the few commercial IGCC plants that have been built to-date; the Conservative Scenario sees no improvements resulting from FE R&D.

- Moderate Technology Innovation Scenario (Moderate Scenario): improvements that result from learning-by-doing enhanced through successful FE R&D but at a level lower than reflected in the Advanced Technology Innovation Scenario; the Moderate Scenario trajectory follows a path through the midpoints of the Conservative and Advanced Scenarios at FE R&D Program milestone dates.

- Advanced Technology Innovation Scenario (Advanced Scenario): improvements that result from learning-by-doing augmented by technology improvements that graduate from a fully successful FE R&D program; the FE R&D improvements assume relevant FE R&D program goals are achieved on schedule targets, with second-generation technologies available by 2025 and transformational technologies available by 2030. (DOE, 2020)

It is important to recognize that estimates of future fossil technology cost and performance for the Advanced Scenario are based on representative technology pathways and should not be interpreted as representing the only technology pathways that enable meeting FE R&D goals. For the 2022 ATB the natural gas pathway represents early improvements to post-combustion carbon capture technology for natural gas combined cycle (NGCC) applications and both the F- and H-class NGCC advanced innovation pathways converge with the subsequent deployment of advanced NG fuel cell (NGFC) systems equipped with 98 percent carbon capture (Iyengar et al., 2022). The coal pathway includes improvements to the base combustion plant (e.g., deployment of high efficiency advanced ultra-supercritical PC plants) as well as improvements to post-combustion capture technology. The coal pathway in the Advanced Scenario does not include improvements to the pre-combustion pathway (e.g., IGCC), and no improvements other than learning-by-doing are included for IGCC in the 2022 ATB.

Assumptions Applicable to All Fossil-Fueled Electricity Generating Technology Options

Fossil-fueled electric generation technology representation in the 2022 ATB include cost and performance estimates for PC and NGCC technology options both with and without carbon capture. Consistent with the 2021 ATB, cost and performance estimates for IGCC and simple-cycle natural gas combustion turbine (NGCT) technology options do not include carbon capture.

All fossil-fueled power plants are evaluated on a common design basis and with similar rigor. For all cases, the design basis assumes a generic Midwestern location in the United States, and performance is evaluated at International Organization for Standardization (ISO) conditions. All fossil-fueled electricity generating technology options include environmental emission controls for criteria pollutants; mercury and hydrochloric acid meet or exceed the 2013 updates to applicable New Source Performance Standards (NSPS); and utility Mercury and Air Toxics Standards meet or exceed new source performance standards and achieve an assumed best available control technology. Plant designs include treatment technologies for liquid waste streams meant to be compliant with the 2015 update to U.S. Environmental Protection Agency's Effluent Guidelines for the steam electric power plant source categories. All plants use mechanical draft evaporative cooling for waste heat rejection.

New-build NGCC and PC power plants equipped with carbon capture all employ state-of-the-art solvent-based post-combustion CO2 capture systems and include multistage compression and dehydration technology producing a dense phase liquid (15.27 MPa, 30oC) at the power plant fence line that is suitable for pipeline transport. Performance estimates are provided for 95% capture for both NGCC and PC applications, discussed in the section "Update of fossil energy technology options with carbon capture capability greater than 90%", below.

An extensive description of the methodology and assumptions used can be found in Cost and Performance Baseline for Fossil Energy Plants Volume 1: Bituminous Coal and Natural Gas to Electricity, Revision 4 (Fossil Baseline). (James III et al., 2019)

Natural Gas-Fueled Electricity Generating Technology Descriptions

The suite of natural gas-fueled electricity generating technology options is consistent with prior releases of the ATB. It includes new-build Brayton cycle (often referred to as simple cycle) combustion turbine (CT) power plants and new-build combined cycle (CC) power plants, the latter with and without post-combustion carbon capture technology.

Natural gas-fueled options available at the start of the 2022 ATB are based on commercially available technologies, including state-of-the-art F-class turbine technology for both CT and CC options. The NGCT F-class technology option represents a single state-of-the-art F-class turbine capable of providing full-load power output of approximately 233 megawatt net output (MW-net) (James et al., 2019). NGCC power plants are configured in a 2x1 configuration using two state-of-the-art F-class combustion turbine/heat recovery steam generator (HRSG) trains. Steam generated in the HRSG is combined to feed a common steam turbine. Steam turbine Rankine cycle conditions are specified to be consistent with steam conditions common to comparable CT-HRSG combinations currently operating today (single reheat, 16.5 MPa/585°C/585°C). NGCC power plants without carbon capture can provide full-load power output of approximately 727 MW-net. (James III et al., 2019)

See section “update of fossil energy technology options” below, for information on technology details with carbon capture and storage.

Coal-Fueled Electricity Generating Technology Descriptions

All new-build PC Rankine cycle power plants (both with and without carbon capture) are sized at nominal 650 MW-net and are designed based on the most advanced steam cycle conditions (single-reheat, 24.1 MPa/593°C/593°C) for which today’s equipment vendors would provide performance guarantees that are acceptable to developers of commercial projects. Note that although the National Energy Technology Laboratory characterizes the Rankine cycle conditions as supercritical, the design conditions are considered by some to be representative of ultra-supercritical steam conditions. New-build coal-fueled integrated gasification combined cycle (IGCC) power plants without carbon are sized at nominal 634 MW-net based on a 2x2x1 configuration using two slurry-fed, oxygen-blown gasification systems (no sparing), each supplying syngas to separate state-of-the-art F-class CTs paired with dedicated HRSGs. Steam from both HRSGs is combined to feed a common steam turbine. The slurry-fed, oxygen-blown gasification technology is the same used at Duke Energy’s Edwardsport Station in Knox County, Indiana, which has been in operation since 2013. (James III et al., 2019) (Turner et al., 2020).

See section “update of fossil energy technology options” below, for information on technology details with carbon capture and storage.

Capital Expenditures (CAPEX)

First-year capital cost estimates are meant to represent “next commercial offering” costs. Next commercial offering costs are not intended to reflect the higher costs or performance challenges often experienced with first-of-a-kind plants; nor do they reflect benefits from cost reductions that result from learning-by-doing that are reflected in comparably lower costs for Nth-of-a-kind plants. To account for learning-by-doing, the out-year projections for the coal and natural gas pathways incorporate both improvements from FE R&D and modest capital cost improvements resulting from learning-by-doing captured by layering capital cost trends from the U.S. Energy Information Administration's (EIA’s) AEO2022 Reference Case. (EIA, 2022)

Current Technology Options: Capital costs represented here are based on bottom-up estimates that begin with steady-state process models that are used to size major plant equipment and define utility (i.e., process steam and auxiliary power needs) and balance-of-plant requirements. Capital cost estimates are provided as total overnight cost, which is meant to capture (1) all on-site facilities and infrastructure that support the plant (e.g., shops, offices, labs, and roads), including direct and indirect labor (Midwest Merit Shop basis) required for its construction and/or installation; (2) engineering, procurement, and construction (EPC) costs; (3) project and process contingencies; and (4) pre-production costs, inventory capital, initial costs for catalysts and chemicals and various other owners' costs. Total overnight costs do not include escalation, interest on debt, or return on equity investment that are typically incurred during construction. An expanded description of the capital cost estimating methodology can be found in the National Energy Technology Laboratory Fossil Baseline (James III et al., 2019). All capital costs for fossil technology options included in the 2022 ATB are reported in constant 2018$ in the respective source documents and have been escalated to constant 2020$ using EIA NEMS escalators (EIA, 2021a) (EIA, 2021b).

Future Capital Costs: Out-year cost projections are aligned with existing FE R&D program goals (DOE, 2020). Future cost improvements reflect achieving targets for reductions in the cost of electricity of CO2 capture-equipped fossil-fueled electricity generating technologies (compared to a 2017 baseline) and are represented as a two-step technology deployment rollout (second generation technologies available by 2025 and transformational technologies available by 2030). Out-year cost estimates are based on representative technology pathways, which include a mix of improvements in performance, capital cost, and operating cost. Several multiple technology pathways have the potential of achieving relevant FE R&D goals.

Capital cost estimate scope is meant to represent a complete power plant facility with the plant boundary limit defined as the total plant facility within the “fence line”. Overnight costs include necessary receiving (e.g., fuel, consumables, etc.) and export (e.g., product, byproduct, waste removal, etc.) infrastructure, with electricity delivery to the bulk power system terminating at the high voltage side of the main power transformers. Capital cost estimates for technology options equipped with carbon capture include all necessary process equipment and infrastructure to deliver CO2 at suitable conditions (i.e., pressure, temperature, and composition) for pipeline transport. No costs are included beyond the fence line for CO2 transport, use or storage.

Operation and Maintenance (O&M) Costs

Operating cost estimates (base year and future) are inclusive of major cost elements associated with operating and maintain a power plant over its expected useful life. Operating costs are segregated into fixed operation and maintenance costs (FOM) and variable operation and maintenance (VOM). FOM includes all labor (operations, maintenance, supervision, and administrative labor) as well as annual property taxes and insurance costs. VOM includes all non-fuel consumables, waste disposal costs (ash, spent catalyst materials, other liquid waste streams), and maintenance materials. (James III et al., 2019) For NGCT, VOM for maintenance materials assumes a starts-based maintenance requirement and assigns a per-start cost and assumed annual number of starts. (James et al., 2019)

Similar to CAPEX, operating and maintenance cost estimates are meant to include all operations within the fence line. Operation and maintenance cost estimates for technology options equipped with carbon capture do not include FOM or VOM for management of CO2 beyond the fence line (i.e., no FOM or VOM associated with transport, use or storage of captured CO2).

Update of fossil energy technology options with carbon capture capability greater than 90%

Targeting net-zero carbon emissions from the power sector highlights the importance of the capture capabilities of decarbonization technologies deployed at fossil-fueled power plants. Historically, technoeconomic analyses of the cost and performance for carbon capture technologies examined 90% reduction of CO2 from fuel combustion exhaust gas. The expansive body of public literature based on 90% capture has resulted in a de facto cap on CO2 reductions at fossil fueled electricity generation and the 10% of uncaptured CO2 presents a challenge to achieving the net-zero objective.

While commercial-scale demonstrations of solvent-based post-combustion CO2 capture systems at coal-fueled power generation facilities has shown the ability to capture 90% of the CO2 in the flue gas stream, ongoing field-tests of post-combustion CO2 capture (PCCC) technology as well as vendor and industry feedback on projects currently in the planning stages, including front end engineering and design (FEED) projects sponsored by DOE, indicate that capture rates as high as 95% are technically feasible for both coal- and natural gas-fueled electricity generating units. There is also a growing body of publicly available literature exploring capture rates even higher than 95% and suggest that carbon capture rates of 97% or higher are achievable on both coal- and natural gas combustion exhaust (IEAGHG, 2019); (Du et al., 2021); (Brandl et al., 2021); (Schmitt et al., 2022).

For this mid-year update to 2022 ATB, FECM is providing updated baseline cost and performance assumptions for new state-of-the-art fossil-fueled power plants including bituminous coal-fueled supercritical PC and NGCC configurations equipped with PCCC. As part of this mid-year update, FECM is expanding the set of NGCC cases by adding cost and performance estimates for H-class combustion turbine-based configurations.

- 95% removal of CO2 on supercritical PC power plants (Coal 95% CCS)

- 95% removal of CO2 on F-class NGCC power plants (NG F-Frame CC 95% CCS)

- 95% removal of CO2 on H-class NGCC power plants (NG H-Frame CC 95% CCS)

- 99% removal of CO2 on SCPC power plants (Coal Max CCS)

- 97% removal of CO2 on F-class NGCC power plants (NG F-Frame CC Max CCS)

- 97% removal of CO2 on H-class NGCC power plants (NG H-Frame CC Max CCS)

In addition to the updated PCCC cases, a “no-capture” H-class NGCC is also provided to allow for better representation of state-of-the-art NGCC options.

- H-class NGCC power plants w/o CCS (NG H-Frame CC)

H-class NGCC power plants are configured similar to the F-class NGCC configuration (i.e., a 2x1 configuration) using two state-of-the-art H-class combustion turbine/heat recovery steam generator (HRSG) trains. Steam generated in the HRSG is combined to feed a common steam turbine. Steam turbine Rankine cycle conditions are specified to be consistent with steam conditions consistent with current designs for commercial offerings (single reheat, 18.5 MPa/585°C/562°C). H-class NGCC power plants without carbon capture can provide full-load power output of approximately 992 MW-net. (Schmitt et al., 2022)

These new cases represent carbon capture processes that achieve high CO2 removal rates viewed to be technically achievable in the near-term using existing solvent-based capture systems. The cost and performance estimates were developed by the DOE FECM National Energy Technology Laboratory (Schmitt et al., 2022) and are directly informed by vendor-supplied performance and costs for carbon capture systems designed for each specified application (i.e., supercritical PC or NGCC) and capture rate (i.e., 95%, 97% or 99%). The new cases have been developed using the same methodology and on a consistent basis with the cost and performance of the corresponding no-capture cases provided by FECM for the 2022 ATB release. Consistent with the 2022 ATB release, the new cases include all necessary process equipment and infrastructure to deliver CO2 at suitable conditions (i.e., pressure, temperature, and composition) for pipeline transport. No costs (capital or operating) are included beyond the fence line for CO2 transport, use or storage.

While design of PCCC systems that capture 95% of the CO2 in combustion flue gas are becoming the norm, there is limited experience in design for real-world capture systems that can routinely, reliably, and economically achieve the higher removal rates (e.g., 97% and greater) suggested by others. As such, the “Max CCS” cases carry greater cost and performance uncertainty than the 95% capture cases.

Estimates for improvements in cost and performance over time (i.e., Conservative, Moderate and Advanced Technology Innovation Scenarios) using the same approach as was done for the 2022 ATB release. It should be noted that Advanced Technology Innovation Scenarios for natural gas converge to the same end state (e.g., NGFC with 98% carbon capture). While the methodology is unchanged, further clarification on the nature of technology progression for the Moderate and Advanced Technology Innovation scenarios is provided as part of the narrative for the mid-year update. Technology advancements portrayed in the Moderate Technology Innovation Scenarios are premised on successful commercialization of 2nd generation technologies (e.g., technologies currently considered to be at technology readiness level (TRL) 6-8. Technology advancements portrayed in the Advanced Technology Innovation Scenarios are premised on successful commercialization of transformational technologies (e.g., technologies currently at TRL 5 or lower).

The endpoints for the Advanced Technology Innovation Scenario are aligned with the endpoint target of the Cost of Energy and CO2 Capture from Advanced Power Systems Government Performance and Results Act (GPRA) Goal and assumes scheduled targets are achieved on time. (DOE, 2020) It should be noted that the Moderate and Advanced Technology Innovation Scenarios included in the 2022 ATB and predecessor releases portray single, continuous trajectories for the respective coal and natural gas technology options. It is important to recognize that there are multiple advanced technology options for providing low-carbon electricity using fossil fuels and to reiterate that the pathways provided in the ATB are representative and not meant to be indicative of specific configurations of 2nd generation and/or transformational technologies.

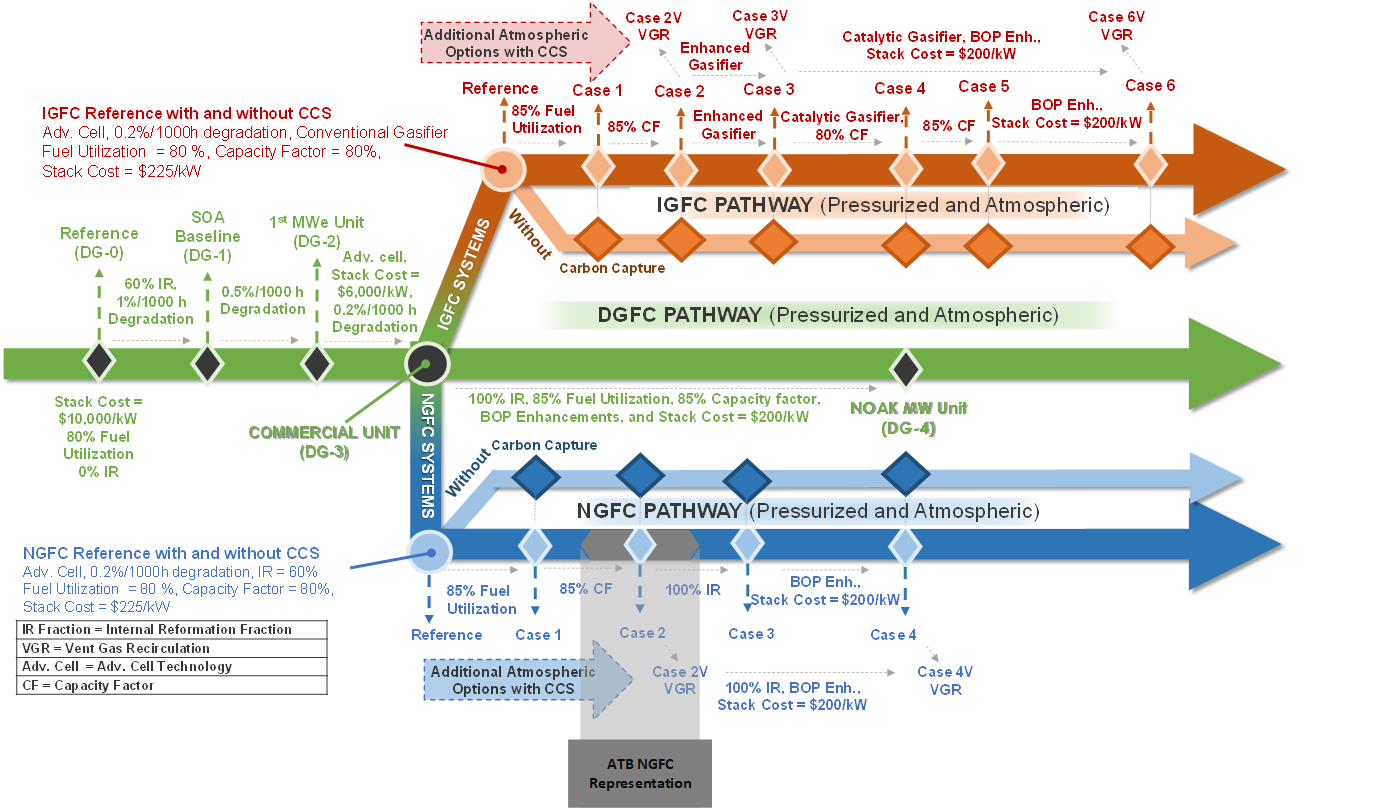

The Advanced Technology endpoint for coal with carbon capture is representative of deployment of pulverized coal combustion plants equipped with advanced ultra-supercritical steam conditions and improvements in cost and performance of the post combustion capture system. The Advanced Technology endpoints for both the F-class and H-class natural gas pathways represent early improvements to post-combustion carbon capture technology for conventional NGCC applications and subsequent deployment of natural gas fuel cell (NGFC) systems capable of 98% carbon capture configured with atmospheric pressure solid oxide fuel cell (SOFC) technology for the topping cycle (see Figure 1 below for representative cost and performance assumptions) paired with a steam Rankine bottoming cycle. All Advanced Technology endpoints for F- and H-class natural gas pathways with carbon capture (e.g., 95% and Max CCS) converge to the same NGFC configuration and share the same cost and performance assumptions.

Figure 1. SOFC Technology Pathways (modified from (Iyengar et al., 2022) to show approximate alignment of ATB NGFC with the NGFC pathway cases in the reference document)

References

The following references are specific to this page; for all references in this ATB, see References.